NOTICE: if pics are blurry, search and download and install in your browser

photobucket blurry fix or similar

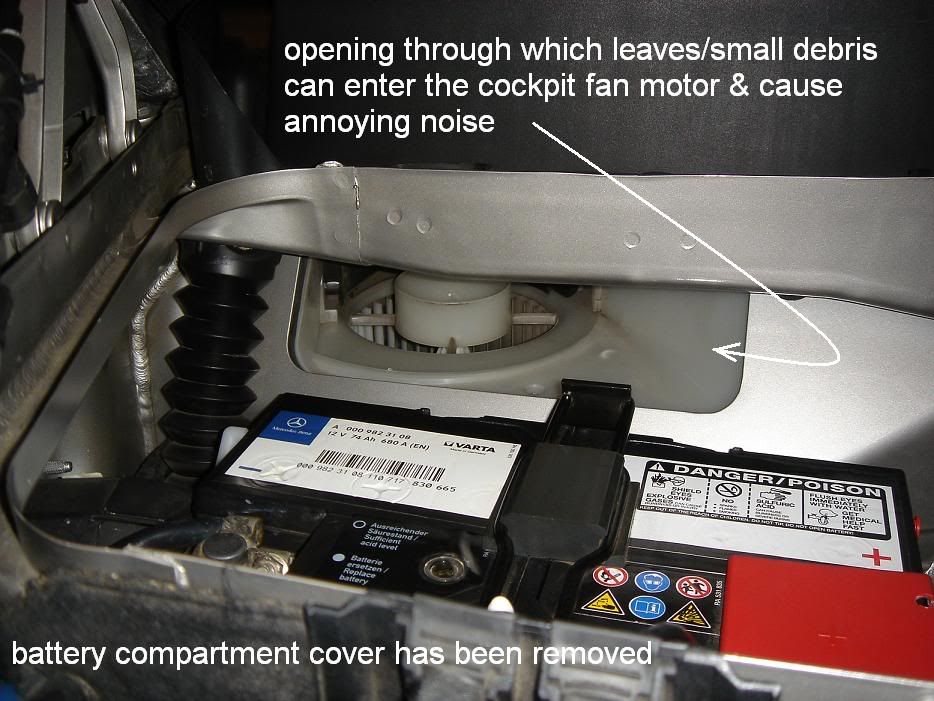

There were a couple of posts about noisy cabin/cockpit fan motor due to leaves which got me thinking.

This is what I came up with today. I hope it will help reduce the risk of leaf/debris ingestion. I've driven the car for some short trips (non-spirited) today after "attaching" the mesh and it had stayed in place. I'll see how it holds up in the next 7 days, including the meet this Saturday (Dec. 5th) and report back.

Below is a photo of the air intake to the cabin/cockpit fan motor:

![Image]()

Pix below shows the mesh in place:

![Image]()

Photo of galvanized steel screen version:

![Image]()

photobucket blurry fix or similar

There were a couple of posts about noisy cabin/cockpit fan motor due to leaves which got me thinking.

This is what I came up with today. I hope it will help reduce the risk of leaf/debris ingestion. I've driven the car for some short trips (non-spirited) today after "attaching" the mesh and it had stayed in place. I'll see how it holds up in the next 7 days, including the meet this Saturday (Dec. 5th) and report back.

Below is a photo of the air intake to the cabin/cockpit fan motor:

Pix below shows the mesh in place:

Photo of galvanized steel screen version: